In the intricate world of construction, precision is paramount. Enter 3D laser scanning—a game-changing technology that is revolutionizing how we approach complex structural elements like post-tension slabs. With the ability to capture detailed spatial data, 3D laser scanning offers a transformative approach to understanding, planning, and verifying post-tension slabs both before and after the concrete is placed. In this article, we delve into how this technology empowers the construction industry, ensuring accuracy and efficiency in this critical phase of construction.

Understanding Post-Tension Slabs

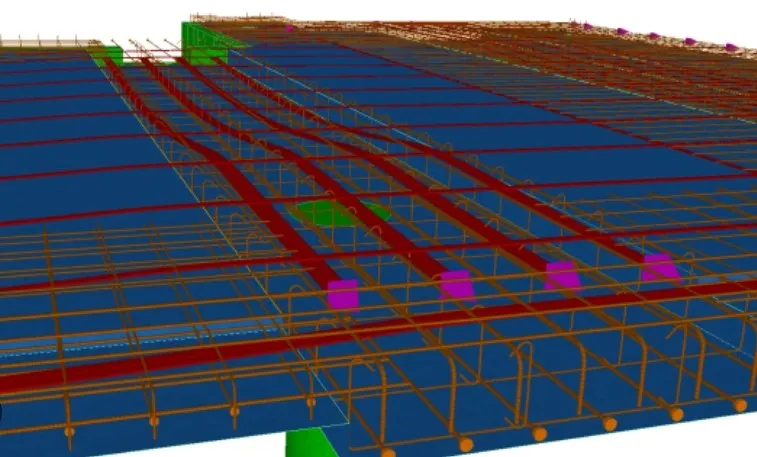

Post-tension slabs are a sophisticated structural solution in construction. These slabs are reinforced with high-strength steel cables (tendons) that are tensioned after the concrete is poured. This process imparts compressive forces onto the slab, enhancing its strength and load-bearing capacity. Post-tensioning allows for longer spans, reduced cracking, and greater design flexibility.

3D Laser Scanning: Before Concrete Placement

Design Verification and Planning

Before concrete is poured, precise planning is essential to ensure that the post-tensioning tendons are properly positioned. 3D laser scanning can be utilized to verify the accuracy of the design plans against the actual site conditions. By creating a detailed 3D model of the project site, scanning technology can identify any deviations from the intended design, providing early insights into potential issues and allowing for adjustments to be made before construction begins.

Clash Detection

In complex construction projects, numerous elements need to coexist harmoniously. 3D laser scanning enables clash detection, identifying any potential interferences between the post-tension tendons and other structural components, utilities, or systems. By detecting clashes early in the planning stage, construction teams can mitigate conflicts, avoid costly rework, and streamline the construction process.

Accurate Tendon Placement

Ensuring precise placement of the post-tension tendons is critical for the structural integrity of the slab. 3D laser scanning provides accurate measurements and visualizations that aid in placing the tendons according to design specifications. The scanning technology offers real-time feedback, allowing construction teams to adjust and fine-tune the placement as needed, ensuring that the tendons are positioned correctly before the concrete is poured.

3D Laser Scanning: After Concrete Placement

Quality Control and Deviation Analysis

Once the concrete is placed and the tendons are tensioned, 3D laser scanning plays a crucial role in quality control. By scanning the post-tension slab after concrete placement, construction teams can create a detailed as-built model. Deviation analysis, often in the form of color-coded heatmaps, highlights any discrepancies between the actual placement of tendons and the intended design. This process ensures that the post-tensioning process was executed accurately, minimizing the risk of structural issues down the line.

Documentation and Verification

Accurate documentation is essential for transparency and accountability in construction. 3D laser scanning generates comprehensive data sets that serve as a permanent record of the post-tensioning process. These data sets include precise measurements, visualizations, and deviation heatmaps. This documentation not only verifies the quality of work but also provides valuable information for future maintenance, renovations, or inspections.

Ongoing Monitoring

The benefits of 3D laser scanning extend beyond the construction phase. Scanning technology allows for ongoing monitoring of the post-tension slabs over time. By periodically scanning the structure, construction professionals can detect potential issues such as tendon corrosion or structural shifts. This proactive approach to maintenance ensures the longevity and safety of the structure.

In the intricate dance of construction, where accuracy and efficiency intersect, 3D laser scanning emerges as an indispensable partner—particularly when it comes to post-tension slabs. From design verification and clash detection to accurate tendon placement and quality control, this technology reshapes the way construction teams approach this critical structural element. The ability to visualize, measure, and analyze post-tension slabs both before and after concrete placement empowers construction professionals to make informed decisions, prevent issues, and ensure the structural integrity of projects. As 3D laser scanning continues to advance, it promises to be an enduring cornerstone of modern construction practices, enhancing safety, reliability, and precision in the built environment.

#3DLaserScanning #PostTensionSlabs #ConstructionPrecision #StructuralIntegrity #InnovativeTechnology #DesignVerification #ClashDetection #QualityControl #ConstructionEfficiency #AccurateDocumentation #OngoingMonitoring #ModernConstruction #BuildingInnovation #StructuralAnalysis #ConstructionInsights #PrecisionScanningAnalytics