Unveiling the Power of 3D LiDAR Scanning: Enhancing FF/FL and Deviation Heatmaps for Concrete Substrates

The world of construction and architecture is constantly evolving, with technological advancements paving the way for more accurate and efficient practices. One such innovation is the use of 3D LiDAR (Light Detection and Ranging) scanning in the construction industry. This cutting-edge technology has revolutionized the way we evaluate concrete substrates for floor finishes, offering invaluable insights into Floor Flatness (FF) and Floor Levelness (FL) as well as deviation heatmaps. In this blog, we will explore how 3D LiDAR scanning has transformed the assessment process and revolutionized the way we receive floor finishes.

Understanding 3D LiDAR Scanning

LiDAR technology employs laser light to measure distances and create detailed 3D representations of surfaces. In the context of concrete substrates, a 3D LiDAR scanner emits laser pulses that bounce off the surface and return to the scanner. They capture precise measurements of the concrete’s contours and irregularities. This collected data is then transformed into a point cloud—a collection of 3D points that accurately depict the surface’s shape.

Floor Flatness (FF) and Floor Levelness (FL) Assessment

Floor Flatness (FF) and Floor Levelness (FL) are essential metrics used to determine the smoothness and uniformity of a concrete substrate. FF refers to the deviations in the flatness of the floor surface over a defined area. FL assesses the variations in the floor’s level across the same area. In the past, FF and FL assessments were conducted manually. By using tools like straightedges and levels, which were time-consuming and prone to human error.

With 3D LiDAR scanning, the assessment process is transformed. The scanner rapidly captures millions of data points across the concrete substrate, offering an extremely accurate representation of its topography. Powerful software algorithms analyze the point cloud data, calculating FF and FL values with unprecedented precision. This data-driven approach significantly reduces human error, delivering reliable and consistent results.

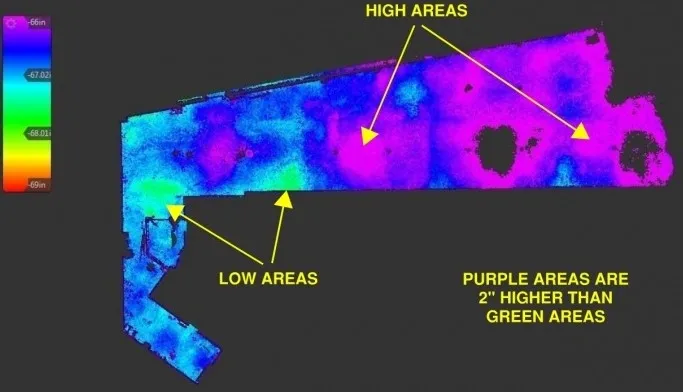

Deviation Heatmaps

In addition to providing FF and FL values, 3D LiDAR scanning generates deviation heatmaps that visually display the variations across the concrete surface. Deviation heatmaps utilize color gradients to represent differences in height or flatness. Areas with minimal deviations appear blue, while areas with higher deviations appear red or orange, providing a clear and intuitive representation of the floor’s condition.

The advantage of deviation heatmaps lies in their ability to identify problem areas and quantify the extent of deviations. This information is invaluable to contractors, architects, and flooring specialists. Now they can precisely plan and execute corrective measures to achieve the desired floor finish.

Benefits and Applications

The implementation of 3D LiDAR scanning for FF/FL and deviation heatmaps has numerous advantages:

- Time-saving: The scanning process is quick and efficient, enabling rapid data acquisition and analysis, saving valuable time during construction projects.

- Precision: The high-resolution data ensures accurate and detailed FF/FL assessments, aiding in better decision-making for floor finishes.

- Cost-effective: Early detection of deviations allows for timely corrections, preventing expensive rework and delays in the construction process.

- Improved Floor Finishes: Contractors can achieve smoother and more uniform floor finishes, meeting strict industry standards and customer expectations.

Unveiling 3D LiDAR Scanning: Enhancing FF/FL and Heatmaps3D LiDAR scanning has revolutionized the way we assess concrete substrates for floor finishes. By providing accurate FF/FL measurements and deviation heatmaps, this technology offers unprecedented insights into the condition of a floor surface. 3D Lidar scanning has many advantages. They are time-saving, precision, cost-effectiveness, and improved floor finishes make it an indispensable tool in modern construction practices. As the technology continues to evolve, we can expect even more advanced capabilities. Thus, further enhancing the construction industry’s efficiency and quality.

Learn more about concrete heat maps here: https://precision3dscanning.com/concrete-elevation-heat-maps/

Learn more about LiDAR here: https://en.wikipedia.org/wiki/Lidar

Make an appointment today to see how we can help with your next project: https://precision3dscanning.com/request-a-quote/

#3DLiDARScanning #ConcreteSubstrateAnalysis #FFFLMeasurement #DeviationHeatmaps #ConstructionInsights #DataVisualization #PrecisionMapping #QualityAssessment #ConstructionTechnology #EnhancedAnalysis #AccurateMeasurements #EfficiencyInConstruction #ConstructionInnovation #www.precision3dscanning.com #precisionscanninganalytics